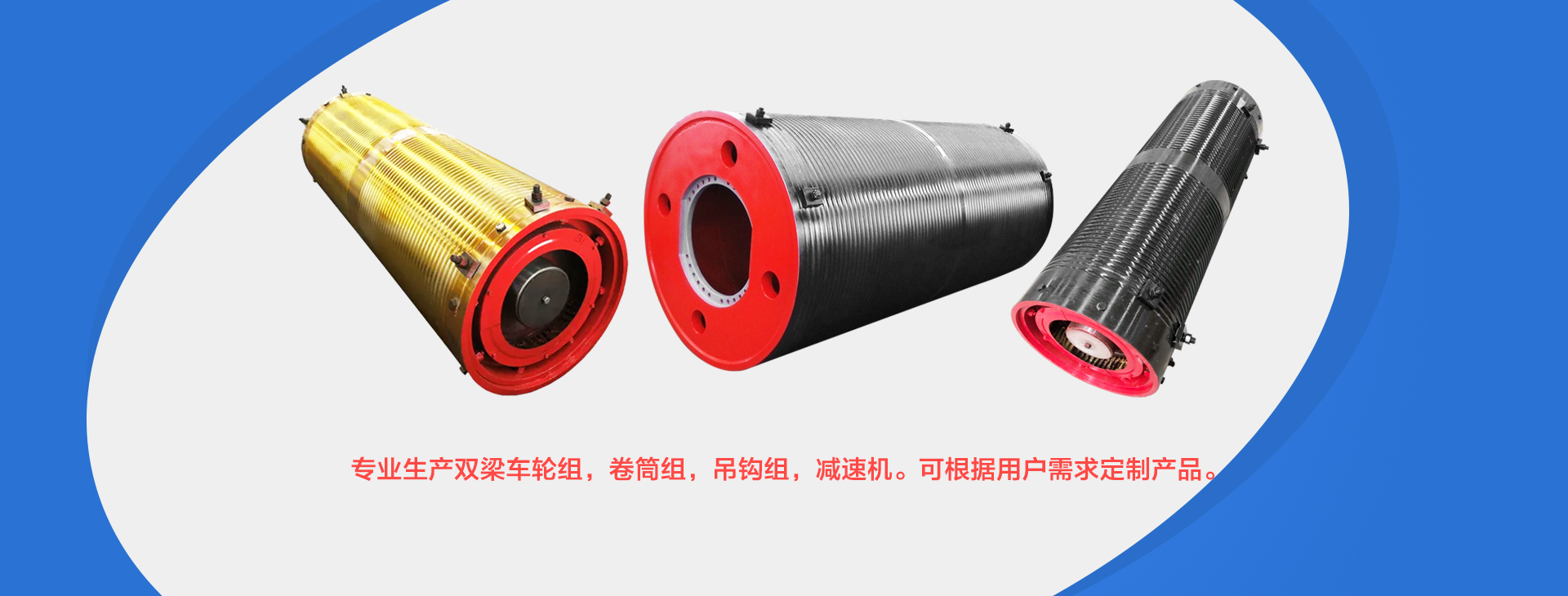

河南省汇力通重工机械有限公司专业生产双梁车轮组质量保障

车轮是用来支承起重机和载荷,并在轨道上使起重机往复行驶运行的装置。车轮主要损伤的形式是磨损、硬化层压碎和点蚀。车轮的材料一般采用ZG430-640铸钢。为了提高车轮表面的耐磨强度和寿命,踏面应进行表面热处理,要求表面硬度为HB300-350,淬火深度不少于20mm。起重机车轮组:起重机运行机构车轮的水平偏斜值是起重机重要的技术参数,偏斜值超差会造成啃轨,增大运行阻力,产生振动和噪音,加剧轨道和车轮磨损,大大降低起重机使用寿命,所以各类起重机制造技术条件都要对车轮水平偏斜规定允许的数值。Henan Huilitong Heavy Industry Machinery Co. , Ltd. specializes in the production of double-beam Wheel set quality assurance to support the crane and load, and on the track to make the crane running back and forth device. The main forms of wheel damage are wear, crush of hardened layer and pitting. The wheel is usually made of ZG430-640 cast steel. In order to improve the wear resistance and service life of the wheel surface, the tread surface should be heat treated, the surface hardness should be HB300-350, the quenching depth should be not less than 20mm. Crane wheel set: the Horizontal deflection value of the wheel of the crane operating mechanism is an important technical parameter of the crane, and the excessive deviation value will cause rail gnawing, increase running resistance, produce vibration and noise, and aggravate the abrasion of the track and the wheel, the crane service life is greatly reduced, so all kinds of crane manufacturing technical conditions must be allowed for the wheel horizontal deflection.